Additive Technology: DLP

Digital Light Projection

- What Is DLP Technology?

Description

Strengths

Weaknesses

Industrial Resins

Medical Resins

- Technical Specifications

Price

Lead Time

Tolerances

Min Wall Thickness

Max Build Volume

Resolutions Available

Advantages Of DLP

Stunning Surface Finish

We can ship beautiful quality, smooth, end-use parts in days. DLP produces exceptional parts with precision tolerances that are needed to meet your production demands.

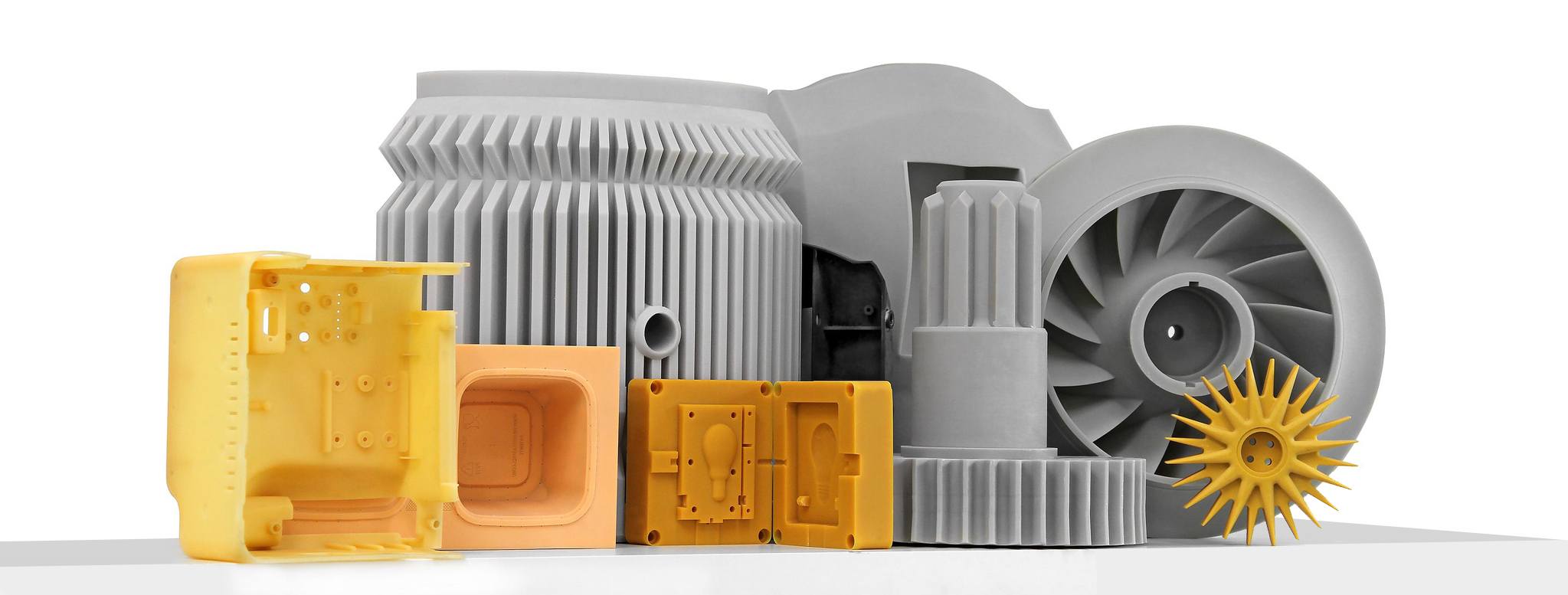

Complex Geometries

Print geometries not possible or too costly with traditional manufacturing methods. DLP allows you to increase efficiency within your designs without increasing cost.

Quick Turnaround

Our fleet of DLP machines are ready to print your parts. We can reduce production lead times from weeks or months to just a few days.

Industrial Grade Materials

We carry standard and engineering grade resins to meet your toughest applications. This allows you to print dimensionally accurate, injection mold like parts that require fit and function.

Reduce Upfront Costs

Save time and money with small batch production runs or produce a limited quantity of parts with no minimums or upfront tooling. DLP is a great way to reduce your costs.

Precise Production Parts

DLP technology is capable of producing precise end-use parts on-demand. We currently support build volumes up to 180 x 101 x 175 mm.

Industrial Grade Parts

Have questions about Digital Light Projection? Our additive specialists can help.

Explore DLP Materials

Below is a list of materials we offer for Digital Light Projection.

ABS Tough

RigidForm

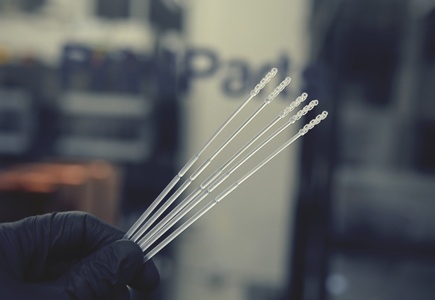

E-Guide Soft

E-Clear