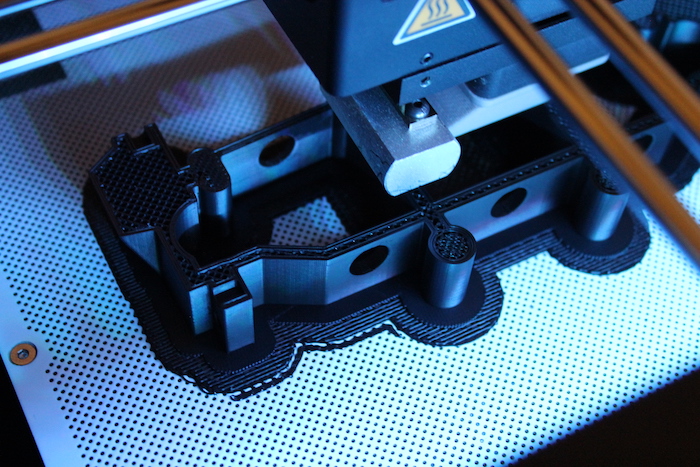

Additive Technology: FDM

HIPS

Great quality parts that are functional enough to be used.

Impact resistant. Low shrink. Exceptional quality.

Print functional parts with very high surface quality.

HIPS is durable enough to support many applications, from prototyping parts to commercial products. It’s a great low cost option for functional parts that require quick turnaround. With a semi-matte finish and low shrinkage, you can print parts at all sizes with no warp or post-processing required.

Part Resolutions

Max Part Size

90 Micron – 0.09 mm

140 Micron – 0.14 mm

190 Micron – 0.19 mm

300 x 300 x 300 mm

( 11.8 x 11.8 x 11.8 in )

Available Colors

Material Properties

Properties

Result

ISO Test

Tensile Strength

16.90 MPa

527:1998

Breaking Stress

13.02 MPa

527:1998

Elongation at Max Stress

1.87%

527:1998

Elongation at Break

7.75%

527:1998

Bending Stress

29.30 MPa

178:2011

Flexural Modulus

1.18 GPa

178:2011

Glass Transition Temp

210º F

11357-3:2014

Izod Impact – Notched

4.82 kJ/m²

180:2004

Applications

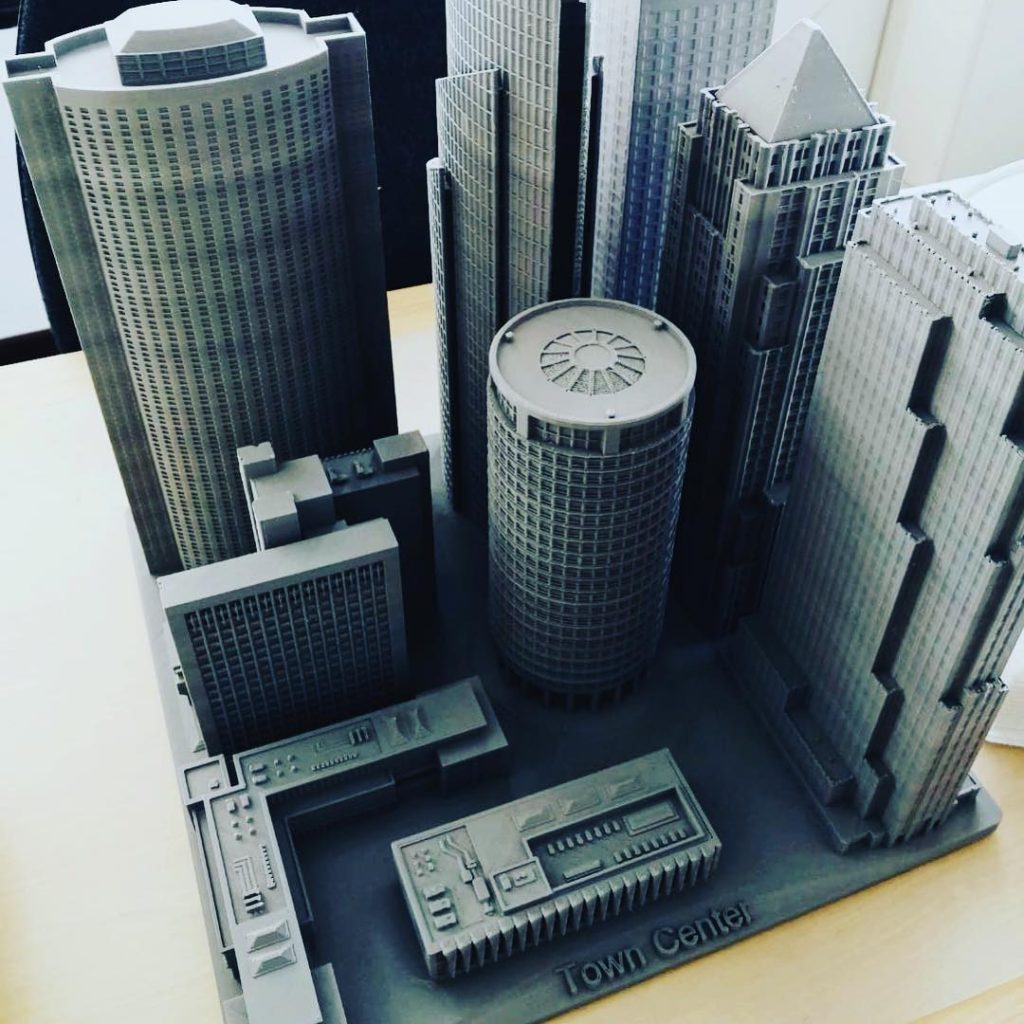

Functional Prototypes

Housings & Enclosures

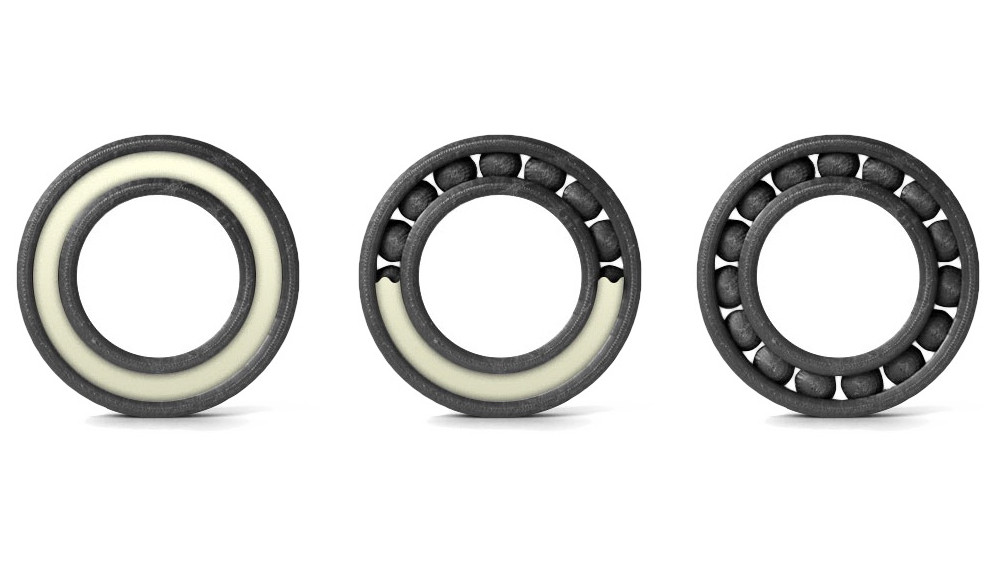

Mechanical Parts

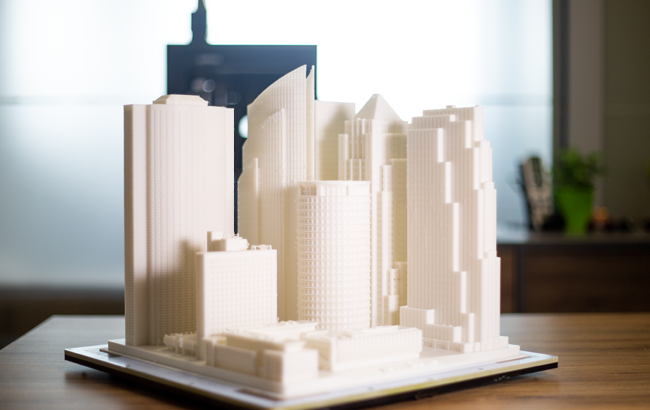

Larger Concept Models

Consumer Product Concepts

End-Use Production Parts

Gadgets & Accessories

Gaming & Toys

Educational Aides

Architecture Mock-Ups

Advantages Of HIPS

Functional Parts

Reliably test part fitment and functionality of your designs. HIPS allows you to print high quality parts that are durable enough to be used.

Surface Quality

With a semi-matte surface that resembles finished products, HIPS can reduce the amount of processing required to hide layer lines.

Impact Resistant

Print functional parts that are durable and impact resistant. HIPS is a great material for performance testing products before production.