Additive Technology: FDM

PET-G

An industrial grade plastic that is strong and chemically resistant.

Parts For Extreme Environments

Print performance parts that won’t degrade over time.

PET-G combines glycol with standard PET to eliminate brittleness, improve durability and increase strength. It’s a UV stable material that won’t shrink and can resist impact along with salts, acids, alkalis, solvents, greases and oils. PET-G is the perfect material to print parts that can endure industrial applications and extreme conditions.

Part Resolutions

Max Part Size

90 Micron – 0.09 mm

140 Micron – 0.14 mm

190 Micron – 0.19 mm

300 x 300 x 300 mm

( 11.8 x 11.8 x 11.8 in )

Available Colors

Material Properties

Properties

Result

ISO Test

Tensile Strength

40.18 MPa

527:1998

Breaking Stress

37.27 MPa

527:1998

Elongation at Max Stress

5.83%

527:1998

Elongation at Break

6.39%

527:1998

Bending Stress

55.30 MPa

178:2011

Flexural Modulus

1.39 GPa

178:2011

Glass Transition Temp

172º F

11357-3:2014

Izod Impact – Notched

3.27 kJ/m²

180:2004

Applications

Chemically Resistant Parts

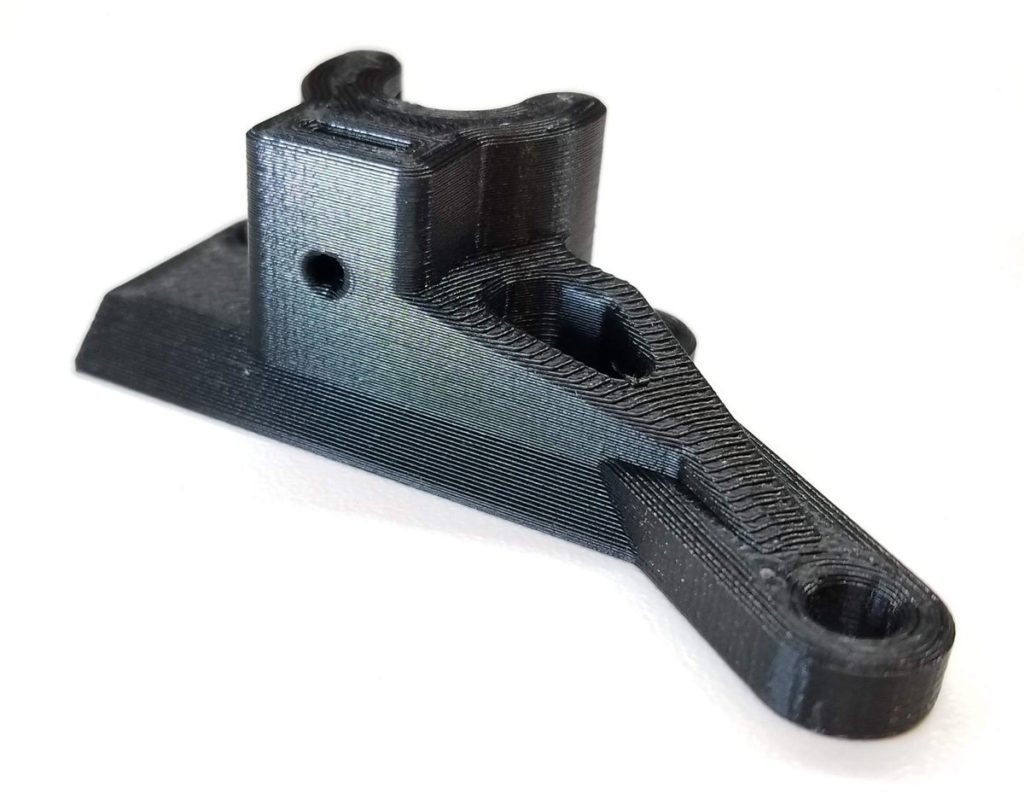

Functional Prototypes

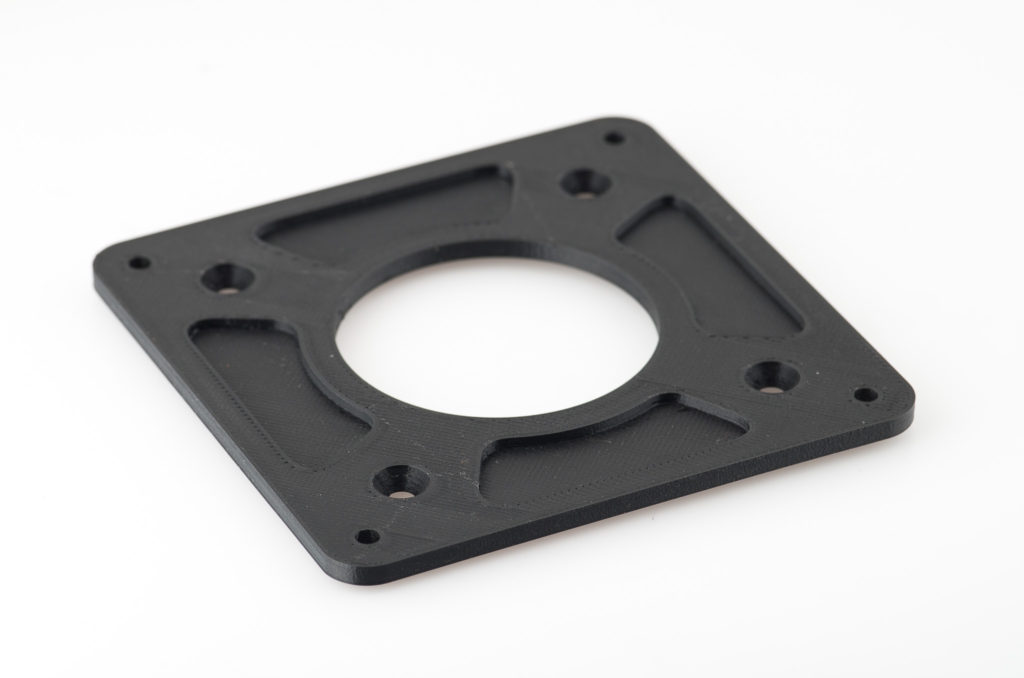

Housings & Enclosures

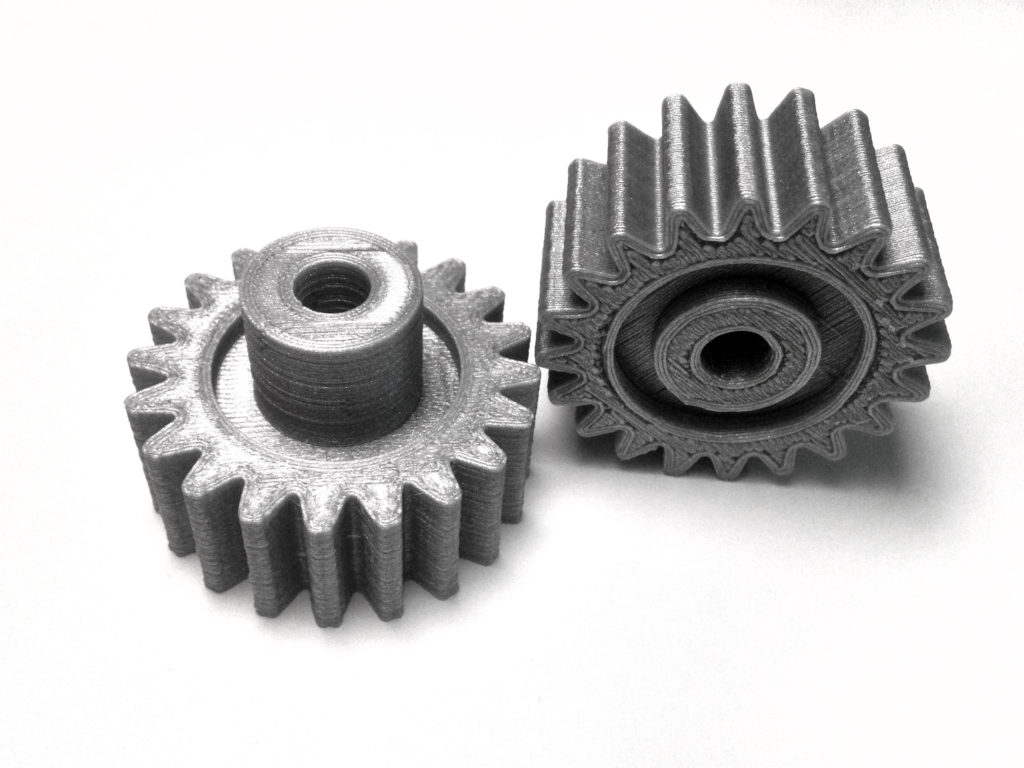

Mechanical Parts

End-Use Industrial Parts

Packaging Prototypes

DIY Projects

Crash Tests

Advantages Of PLA

Chemically Resistant

PET-G is resistant to salts, acids, alkalis, solvents, greases and oils. It’s a great choice for parts that have to withstand extreme environments.

Impact Resistant

Use PET-G when printing parts that need to be durable and impact resistant. It’s the perfect material for creating performance parts.

Very Low Shrinkage

Print large parts or small intricate mechanisms that are dimensionally stable, PET-G can print reliable parts with very little or no shrinkage.