Additive Technology: SLS

Nylon 12

A polymer that’s strong, durable and flexible.

Production Grade Parts

Print quality parts with industrial grade strength.

Balancing strength and detail, Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts. It is environmentally stable, resistant to chemicals, abrasion, and fatigue, while maintaining excellent quality and fine detail.

Part Resolutions

Max Part Size

100 Micron – 0.1 mm

165 x 165 x 320 mm

( 6.5 x 6.5 x 12.6 in )

Available Colors

Properties

Result

Test Method

Tensile Strength

50 MPa

ASTM D638 Type 1

Tensile Modulus

1850 MPa

ASTM D638 Type 1

Elongation at Break (X/Y)

11%

ASTM D638 Type 1

Elongation at Break (Z)

6%

ASTM D638 Type 1

Flexural Strength

66 MPa

ASTM D638 Type 1

Flexural Modulus

1600 MPa

ASTM D638 Type 1

Heat Deflection @ 1.8 MPa

189º F

ASTM D790 A

Izod Impact – Notched

32 kJ/m²

ASTM D790 A

ASTM D648

ASTM D256

Applications

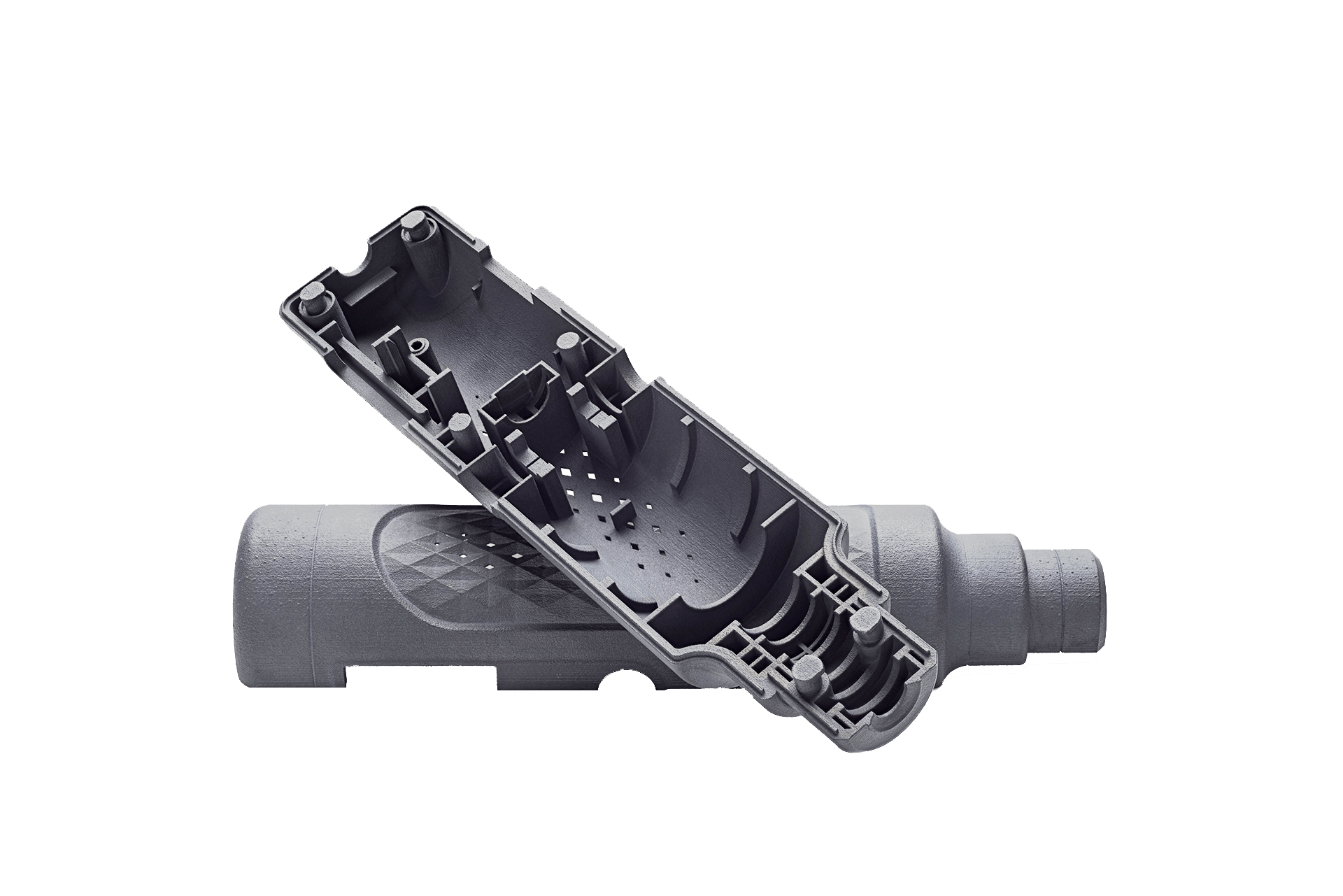

Functional Prototypes

Housings & Enclosures

Mechanical Parts

End-Use Production Parts

Assembly Line Fixtures

Inspection Hardware

Jigs, Brackets & Chassis Parts

Production Tooling Development

Exceptional Quality

Nylon 12 can be delivered in a natural grey finish or dyed pure black.

Advantages Of Nylon 12

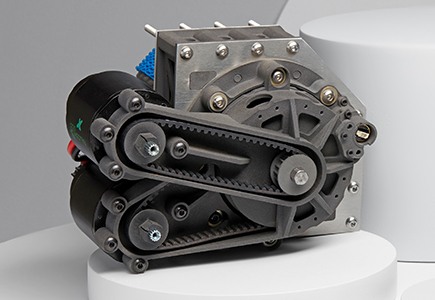

Industrial Strength

Nylon 12 has a high impact resistance, which makes it a great material for industrial applications that require added strength and durability.

Production Volume

Fast print speeds, high-density nesting and no support structures allow for maximize use of build volume to print more parts with less lead time.

Excellent Quality & Detail

Create complex parts with superior strength and accuracy. Nylon 12 provides incredible resolution, edge definition and surface finish.

Need help choosing a material?

We can help you find the right material for your application.

1-866-28SPM3D

(1-866-287-7633)

142 Lafayette St.

Newark, NJ 07105

made@spm-3d.com