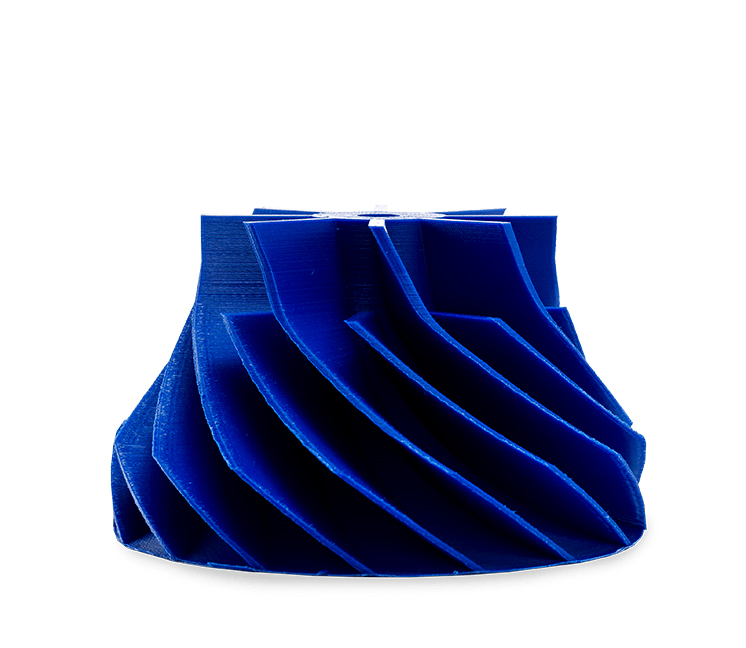

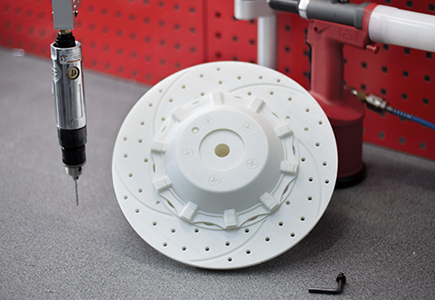

Additive Technology: FDM

ABS

Available in a wide range of colors, ABS is a low cost thermoplastic that’s tough enough for prototyping and manufacturing functional parts.

Affordable, Functional Parts

ABS is a common plastic with good mechanical properties, higher than PLA but with less detail.

Tough enough for mechanical and functional parts, cheap enough to tackle iterative design and production. ABS is a great low cost option for parts that require quick turnaround. With a matte finish and a wide range of colors, ABS parts can be sanded, chemically smoothed and post-processed easily.

Part Resolutions

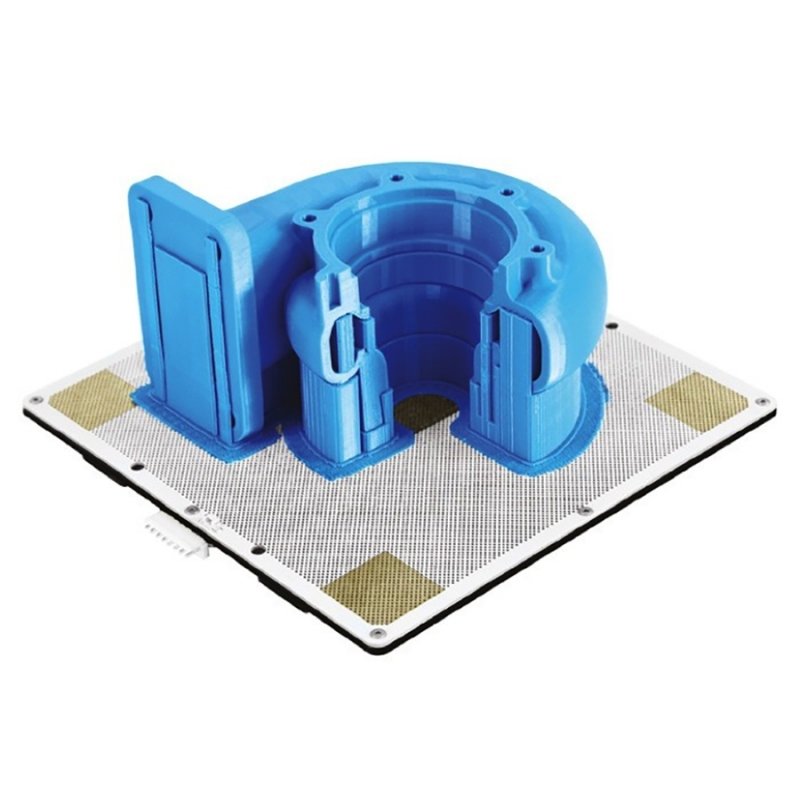

Max Part Size

90 Micron – 0.09 mm

140 Micron – 0.14 mm

190 Micron – 0.19 mm

300 x 300 x 300 mm

( 11.8 x 11.8 x 11.8 in )

Available Colors

Material Properties

Properties

Result

ISO Test

Tensile Strength

30.46 MPa

527:1998

Breaking Stress

25.89 MPa

527:1998

Elongation at Max Stress

4.52%

527:1998

Elongation at Break

11.08%

527:1998

Bending Stress

46.20 MPa

178:2011

Flexural Modulus

1.08 GPa

178:2011

Glass Transition Temp

226º F

11357-3:2014

Izod Impact – Notched

8.93 kJ/m²

180:2004

Applications

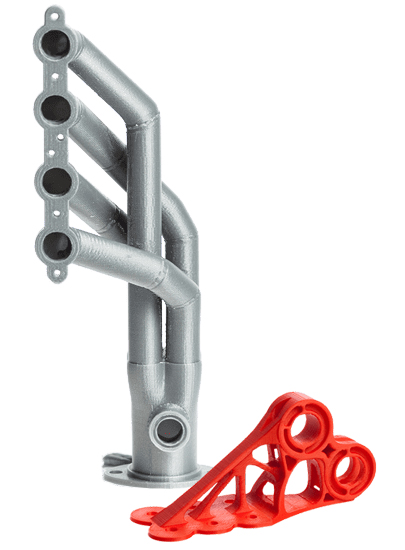

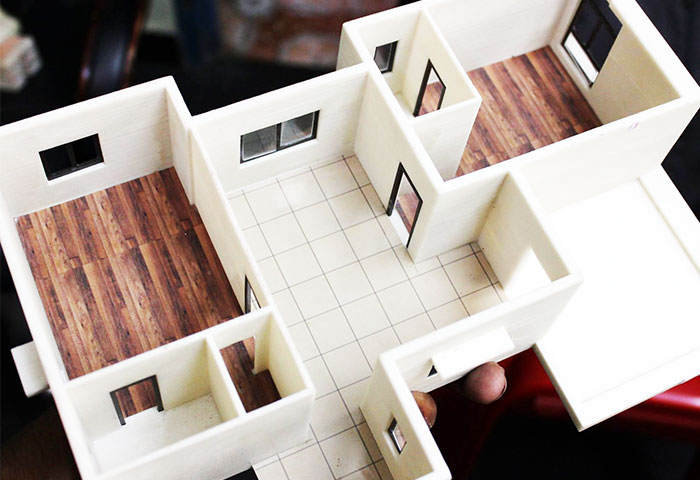

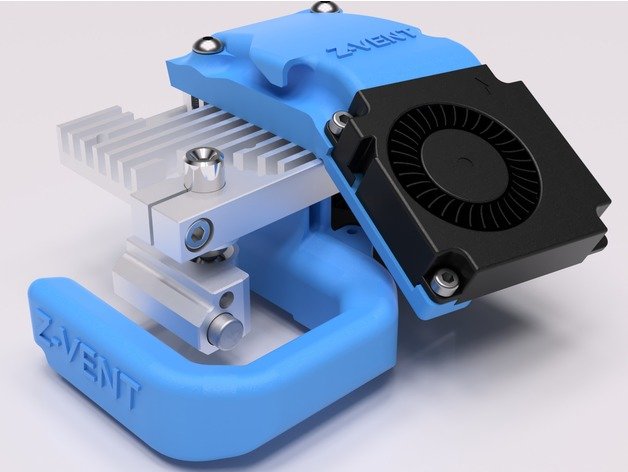

Functional Prototypes

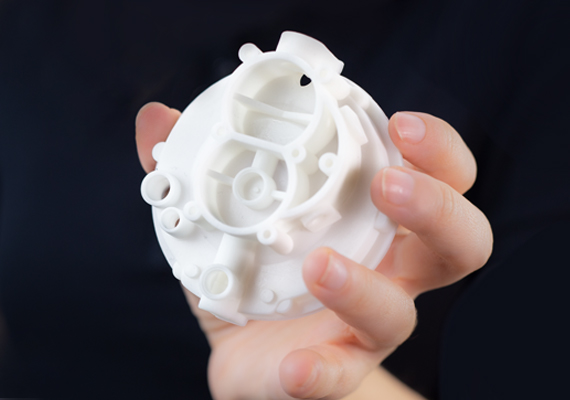

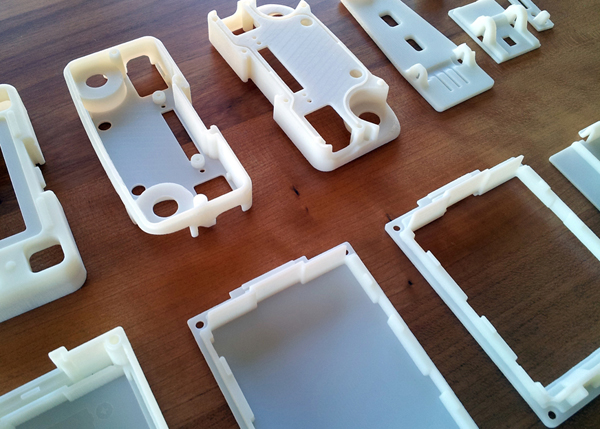

Housings & Enclosures

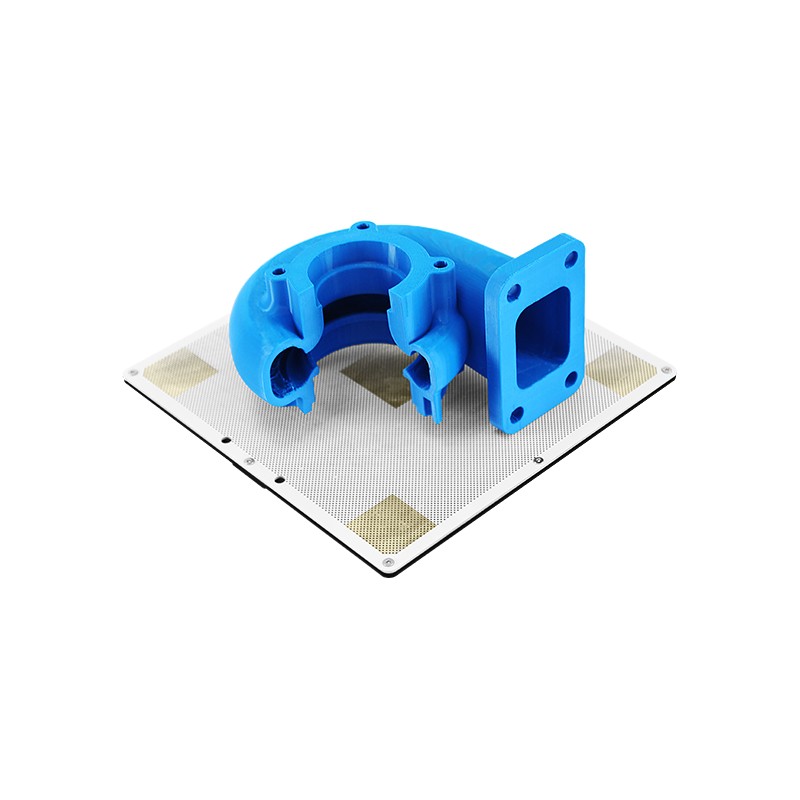

Mechanical Parts

Concept Models

End-Use Production Parts

Gadgets & Accessories

DIY Projects

Gaming & Toys

Educational Aides

Advantages Of ABS

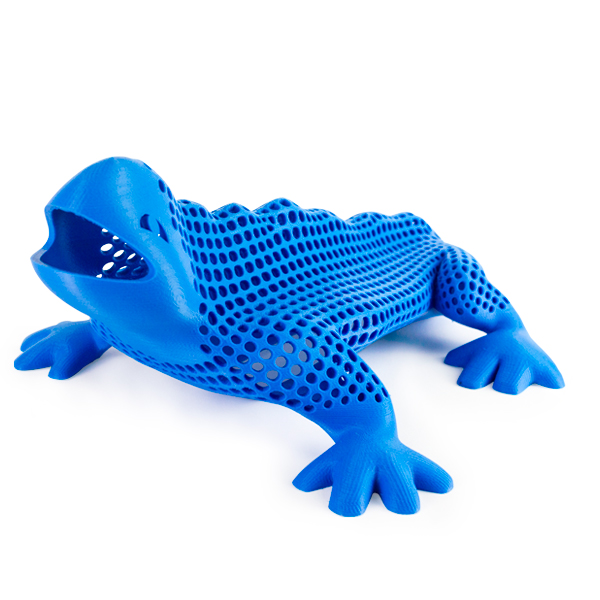

General Purpose

ABS prints with a matte surface and comes in a wide color range, it’s a great choice for general purpose prototyping and end-use parts.

Affordable Parts

Ease of use and low cost make ABS the perfect material for iterative design projects, rapid prototyping and even small scale production on a budget.

Easy Post Processing

ABS can be post-processed using various methods. Parts can be smoothed with acetone vapors, hand sanded and even painted.

Are you ready to Print Parts?

We work with some of the best teams in the world.