Additive Technology: FFF

Fused Filament Fabrication

- What Is FFF Technology?

Description

Strengths

Weaknesses

Base Materials

Reinforcement

- Technical Specifications

Price

Lead Time

Tolerances

Min Wall Thickness

Min Fiber Wall Thickness

Max Build Volume

Resolutions Available

Advantages Of FFF

Industrial Strength

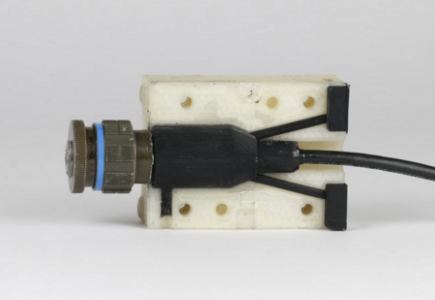

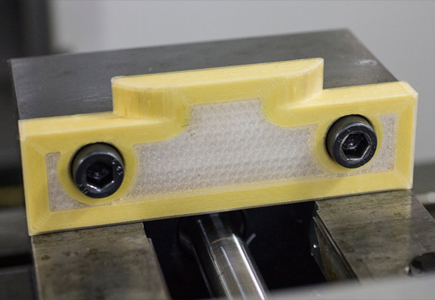

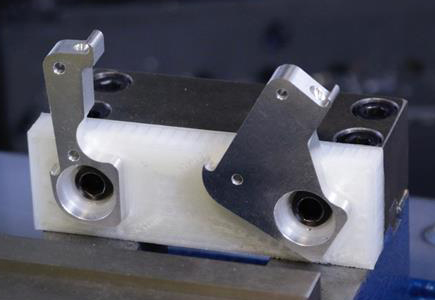

FFF uses a material called Onyx, it’s a Nylon based material with chopped carbon fiber. Onyx is high strength with excellent heat resistance, surface finish, and chemical resistance.

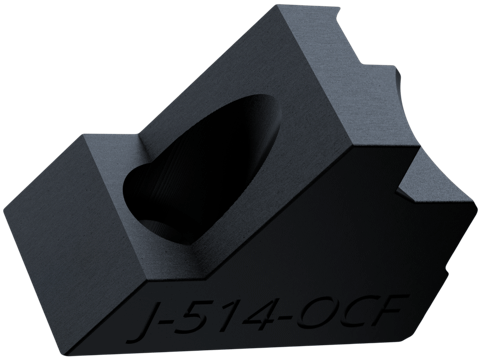

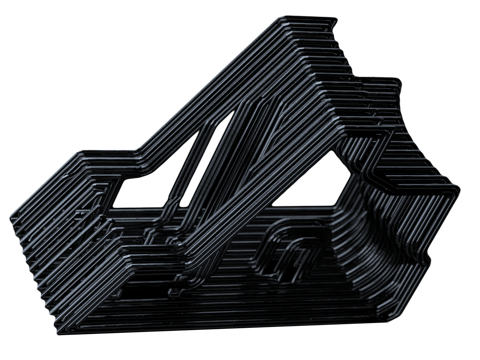

Complex Geometries

Print geometries not possible or too costly for CNC machining. This allows you to increase efficiency within your designs without increasing cost.

Quick Turnaround

Our fleet of FFF machines are ready to print your parts. We can reduce production lead times from weeks or months to just a few days.

Composite 3D Printing

We can add continuous fiber reinforcement to the internal structure of your parts, this allows us to print composite parts that achieve unparalleled strength, stiffness and durability.

Exceptional Quality

Go from CAD to beautiful quality, strong, end-use parts in days. Onyx has a shimmery surface that hides layer lines and produces exceptional parts.

Large Build Volume

We can print Onyx on it’s own or reinforced with continuous fiber and produce large build volumes up to 330 x 270 x 200 mm.

Performance Parts On-Demand

Industrial Strength Materials

Explore FFF Materials

ONYX

NYLON

CARBON FIBER

KEVLAR

FIBERGLASS