Additive Technology: SLA

High Temp Resin

High Temp Resin for high thermal stability.

High Temperature Resistance

High Temp offers a heat deflection temp of 460° F

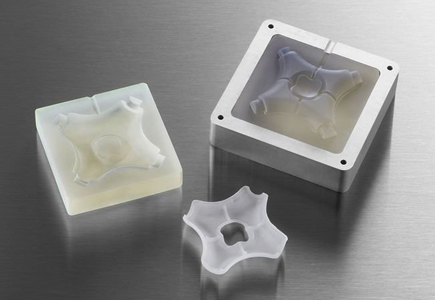

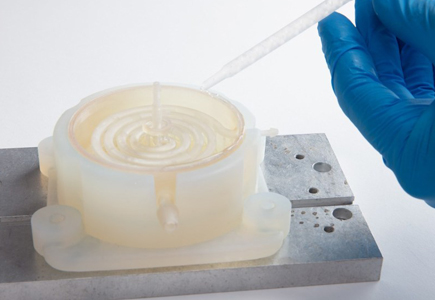

High Temp Resin has the highest heat deflection temperature of all our resins. It can resist temps up to 460° F and endure high heat applications. Use it to print precise parts with a matte surface finish and transparent appearance. High Temp Resin works great for printing heat resistant parts like injection molds and mold inserts.

Part Resolutions

Max Part Size

25 Micron – 0.025 mm

50 Micron – 0.05 mm

100 Micron – 0.1 mm

145 x 145 x 175 mm

( 5.7 x 5.7 x 6.9 in )

Available Colors

Material Properties

- Nylon

Onyx / CF

6061 Aluminum

ABS

Nylon

Properties

Result

ASTM Test

Tensile Strength

58.3 MPa

D 638-14

Tensile Modulus

2.75 GPa

D 638-14

Elongation

3.3%

D 638-14

Flexural Modulus

2.62 GPa

D 790-15

HDT at 0.45 MPa

460.4º F

D 648-16

Izod Impact – Notched

18.2 J/m

D 256-10

Applications

Parts Requiring High HDT

Functional Prototypes

Housings & Enclosures

Injection Molds & Inserts

Manifolds, Valves & Pipe Parts

End-Use Production Parts

Heat Resistant Automotive Parts

High Heat Jigs, Fixtures & Tooling

Advantages Of High Temp

High Heat Deflection

High Temp Resin has a high heat deflection of 460.4° F. This makes it great for parts that require high thermal stability and heat resistance.

Exceptional Quality

Print exceptional quality high temp parts at 25, 50 and 100 microns. Use High Temp Resin to print precision parts for high heat applications.

Smooth Matte Surface

High Temp Resin carries a smooth matte surface and transparent appearance. It’s great for precise parts and prototypes that need to endure.

Need help choosing a material?

We can help you find the right material for your application.