Additive Technology: FFF

HSHT Fiberglass Reinforcement

HSHT stands for High Strength and High Temperature.

Highest Impact Resistance

Onyx parts with HSHT are 29x more impact resistant than ABS and over 100x more impact resistant than PLA.

Parts reinforced with HSHT Fiberglass can achieve a greater strength and heat tolerance than Aluminum. HSHT has the highest impact resistance and heat deflection temp at 302º F. It’s best suited for parts that require a repeated load or sudden impacts while enduring higher operating temperatures.

Resolution Supported

Max Part Size

100 Micron – 0.1 mm

330 x 270 x 200 mm

( 12.9 x 10.5 x 7.8 in )

Exterior Materials

Material Tech Specs

- Heat Deflection Temp

- Impact Resistance

- Elastic Deflection

Onyx / CF

6061 Aluminum

ABS

Nylon

Onyx / CF

6061 Aluminum

ABS

Nylon

Onyx / CF

6061 Aluminum

ABS

Nylon

Material Properties

Result

ASTM Test

Tensile Strength

600 MPa

D3039

Tensile Modulus

21 GPa

D3039

Tensile Strain at Break

3.9%

D3039

Flexural Strength

420 MPa

D790

Flexural Modulus

21 GPa

D790

Flexural Strain at Break

2.2%

D790

Compressive Strength

192 MPa

D6641

Heat Deflection Temp

302º F

D648 B

Izod Impact – Notched

3100 J/m

D256-10 A

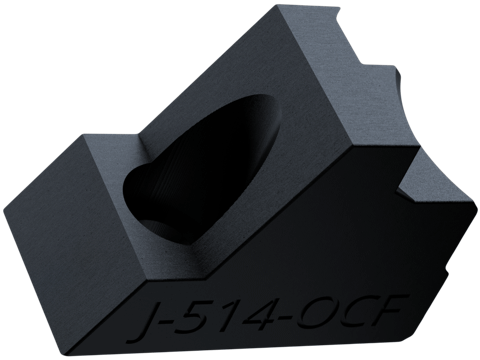

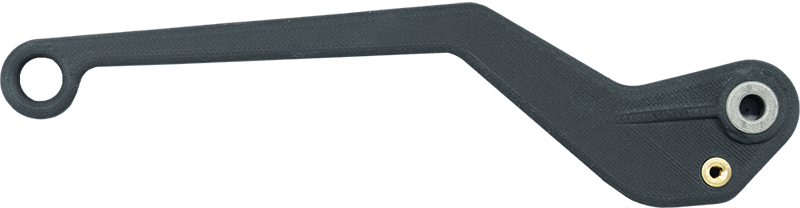

Applications

Functional Prototypes

Mechanical Parts

Thermoforms

Welding Fixtures

Inspection Hardware

Jigs, Brackets & Chassis Parts

End-Use Production Parts

Housings & Enclosures

High Strength

Onyx parts printed with HSHT Fiberglass are 2.5x stronger and 8x stiffer.

High Heat Reinforcement

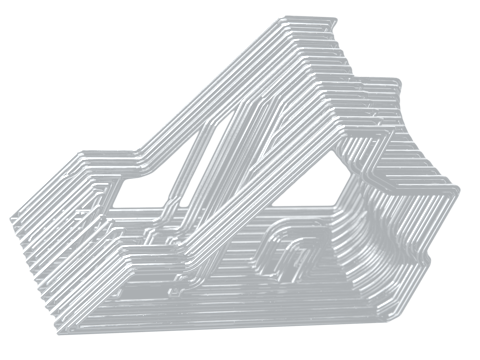

Print parts with an exterior base material and add HSHT Fiberglass reinforcement.

- Onyx Exterior

- HSHT Fiberglass Reinforcement

Advantages Of HSHT Fiberglass

High Impact Resistance

HSHT delivers the highest impact resistance of all our reinforcements. It’s 29x more impact resistant than ABS and 100x more than PLA.

High Strength

Reinforce your Nylon and Onyx parts with HSHT Fiberglass to achieve a higher flexural strength and tensile strength than Aluminum.

High Heat Deflection

HSHT Fiberglass has the highest heat deflection temperature of 302º F. It’s great for strong parts that require sudden impacts in high temps.

Need help choosing a material?

We can help you find the right material for your application.